ABSTRACT

The global shipping industry depends on the developing nations to dispose of the end-of-life vessels, which will no longer float in the seas. The developed world has gone out of the scene of this disposal process or shipbreaking, to safeguard their environment and people and comply with the international standard. Developing countries like Bangladesh got their hands in this dirty business to get scrap steel and thereby run the economy. However, the scar being left by the shipbreaking industry cannot be covered by the growing economy. Occupational and environmental health risks associated with ship dismantling is deteriorating for years in Bangladesh. Decades after the booming of the industry, the barriers towards strict legal implementation still stand along the way. Shutting down the industry is not possible for Bangladesh due to its great impact on the national economy, but ensuring the rule of law and practicing green ship recycling can certainly reduce the negative consequences of the hazardous industry.

INTRODUCTION

The shipping industry, a strong base of the world economy, promotes the trade of goods on one hand and runs the trade of toxic waste on the other. Ocean-going ships carry over 80% of the goods in international trade which is mostly owned by developed countries (Demaria, 2010). However, when these vessels reach the end-of-life phase, they move to the shores of developing countries to get demolished along with their toxic materials. Despite knowing the associated risk of environmental degradation and labor rights violation, developing nations thrive to run this ship scrapping business, so that their economy stays upright. Bangladesh started running the shipbreaking industry right after its independence in 1971, but unfortunately, the concern regarding marine ecology and the laborers involved continues to date. Decades of laxity turned the shipbreaking yards into deadly junkyards, where the maritime environment is taken for granted and workers are considered mere numbers and statistics. The compliance of the Bangladeshi government towards international regulations remained questioned. This paper addresses the economic role of shipbreaking yards in Bangladesh and examines the environmental and human costs of the industry. Investigating the challenges of legal implementation in Bangladesh, it suggests pathways for safer ship recycling.

Shipbreaking industry in Bangladesh: a brief overview

Shipbreaking, also synonymous with ship recycling or scrapping is the dismantling of outmoded watercraft for disposal (Aktaruzzaman, et al., 2014). The operational life of ships comes to an end in shipbreaking yards, also called ship graveyards or ship symmetries. Usually, ships that serve 20-30 years in the ocean are sent to shipbreaking yards for dismantling (Sujauddin, et al., 2015). To allow the contemporary updated ships to join the fleet, ship dismantling is necessary. It is also needed to reuse the steel content of the ship that covers 95% of its mass (Rahman, 2020). Being a labor-intensive industry shipbreaking became less profitable in the industrialized nations like the UK and USA who once dominated in the business. With the emergence of strict environmental and labor safety regulations, the industry moved to semi-industrial nations, characterized by an abundance of cheap labor and negligence towards environmental and labor rights. Now Bangladesh, India, Pakistan, Turkey, and China are responsible for over 90% of the global ship recycling (Gunbeyaz, et al., 2019).

The commercial shipbreaking journey of Bangladesh started in 1974, following the purchase of a damaged Pakistani ship by Karnafully Metal Works Limited (Hossain and Islam, 2006). The ship got damaged in the liberation war of 1971 and was later rescued by a Soviet rescue team. 50 shipbreaking yards were established in Bangladesh since 1974, which scrapped 52% of the global end-of-life ships (Alam and Faruque, 2014). In 1984 Bangladesh became one of the largest shipbreaking countries in the world (Hossain, 2015).

The cluster of shipbreaking yards in Bangladesh is found mostly in the Shitakunda-Bhatiyari coast of Chittagong, the port city (Sujauddin, et al., 2015). The favorable climate of this coastal zone, availability of cheap labor, and irregular environmental supervision made the city a shipbreaking paradise (Alam and Faruque, 2014). During the first decade of the twenty-first century, Bangladesh scrapped 30 % of the global Light Displacement Tons (LDT) and dismantling over 200 ships, it ranked 3rd among the largest shipbreaking countries in 2013 (Rabbi and Rahman, 2017). In the first half of 2020, Bangladesh stood second in ranking dismantling 74 ships while India ranked 1st with 95 ship scrapping (Sayem, 2020).

Shipbreaking industry and Bangladesh economy

The shipbreaking industry holds a significant position in the Bangladeshi economy. For thousands of people being a laborer in shipbreaking yards is the only source of income. Approximately 25,000 people are directly employed in shipbreaking activities, while 200,000 more are involved in other businesses linked to shipbreaking (Hossain, et al., 2016). Shipbreaking industries also provide much-needed steel for Bangladesh, since it has no iron ore. New ships that get added to the local fleet rely heavily on the scrap steel from shipbreaking industries. Over 350 re-rolling industries like heavy and light engineering industries also depend on the scrap steel from shipbreaking industries as their raw materials (Hossain, et al., 2016). Shipbreaking industries also provide a wide range of second-hand machinery. Locals have a strong demand for foreign ship machineries like electric fittings and generators, believing these are more durable than the local products. Shipbreaking industries are also an important source of government revenue. Bangladesh government earns a revenue of 700 crores BDT annually from duties and yards tax imposed on these industries. (Hossain and Rahman, 2010). Other than fulfilling the local demand, Bangladesh is emerging as a steel exporter country with its scrapped steel reservoir. In 2009 African countries imported more than 85,000 tons of steel from Bangladesh (Khan, 2010). According to Hossain (2015), shipbreaking industries contribute to about 2 billion USD in the Bangladeshi economy. From these statistics, it can be easily anticipated how Bangladesh’s economy will suffer if the industry collapses. Because of this strong economic impact ship breaking industry always get escaped from the allegations of environmental degradation and violation of labor rights.

Read More: Partition of India and the Role of Indian National Congress

Shipbreaking yards of Bangladesh: an environmental perspective

Environmental justice is a forever questioned issue for the shipbreaking yards of Bangladesh. The way they operate their day to day activities is damaging the environment in every aspect-soil, water, surrounding air, marine and terrestrial life nothing can escape from its catastrophic belt.

Polyvinyl Chloride (PVC), Polycyclic Aromatic Hydrocarbon (PAHs), Polychlorinated Biphenyl (PCB), and other heavy metals of the vessels frequently come in contact with the soil and pollute its properties (Rabbi and Rahman, 2017). Activities related to compressors and pumps of the ships are often operated in the open space-which severely pollute the soil. Siddiquee, et al. (2012) found that the concentration of trace metal in the beach soil exceeds the normal level. World bank research of 2010 showed that improper handling of poisonous materials caused contamination of sea beach soil in Bangladesh (Rabbi and Rahman, 2017). In Shitakunda, contaminated beach soil led to the disruption of forest cover and coastal erosion (Kutub, et al., 2017).

Bangladesh does not have the proper technology to manage hazardous waste. Materials that contain asbestos can form carcinogenic powder while dismantling and pollute the air. Deconstruction of refrigeration in the yards causes the release of greenhouse gases in the air like chlorofluorocarbons. Toxic gases like polychromatic hydrocarbons and dioxins emit due to the improper stripping of electric cables (Zakaria, et al., 2012).

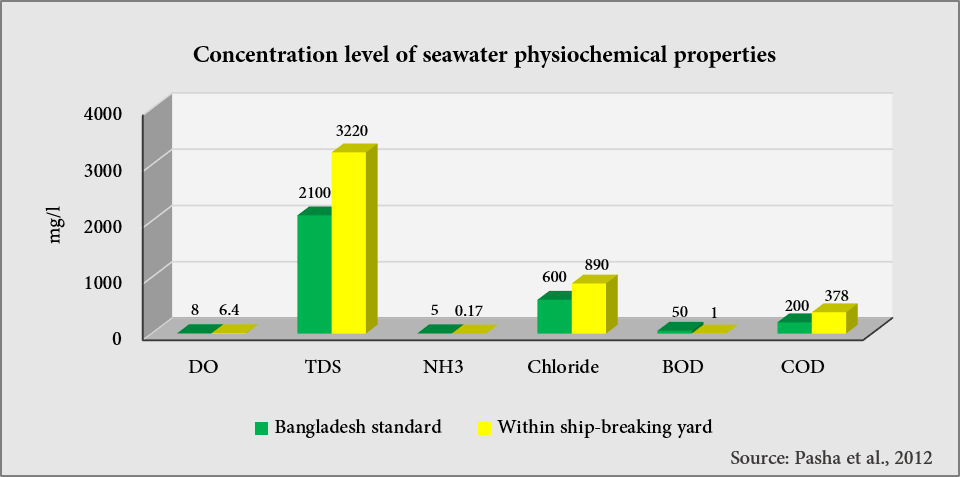

The physicochemical properties of seawater are severely spoilt by the liquid waste from the dismantled ships like paint, salt, ammonia, and acids (Pasha et al., 2012). Some of the properties are found to be existing far beyond the suggested limit (as the figure shown below).

The double bottom often contains ballast water which is not well-considered while slicing the ship. This release of ballast water or bilge causes serious pollution to the seawater (Zakaria, et al., 2012). In Bangladesh, the standard value for the concentration of oil and grease is 10 mg/l, but the seawater adjacent to the shipbreaking yards has a concentration far beyond the limit- 9280 to 10,600 mg/l for oil and 52.5–123.5 mg/l for grease (Hossain and Rahman, 2010).

Deforestation and loss of biodiversity are alarmingly increasing in the shipbreaking yard dominated regions. Kutub, et al. (2017) found that in Sitakunda shipbreaking yards expanded from 3.45 km strip of sea beach in 1989 to 12.78 km in 2010, showing an increase of 300%. PAHs-released from ships while dismantling can be absorbed by the marine organisms via food chain or inhalation. This can cause malicious tumors and even death of these organisms. Sometimes PAHs combine with DNA and damage cells.

Phytoplanktons and zooplanktons of the sea are dying due to the release of toxic substances into the seawater. This is further decreasing the fish resource since they are facing food scarcity. Many of the fish species are no longer found in the Sitakunda area such as-Kala tailla, Nandi bailla, Kala poa, and many more (Kutub, et al., 2017).

The marine ecosystem in the yard area is on the verge of collapse. It seems like nobody cares about the environment as long as the economy is served.

Shipbreaking yards of Bangladesh: Workers’ perspective

The ship-breaking yards of Bangladesh pose a hazardous occupational environment for the laborers involved ( Zakaria et al., 2012). Despite employing thousands of people health and safety issues in the yards are overlooked in such a way that it may seem the industry is run by non-humans. Foreign ship owners and local shipyard authorities- everyone wear a blindfold to get their job done, even if the price of the job is precious human lives.

Usually, most of the workers in the shipbreaking yards are unskilled, the risk and hazard associated with shipbreaking are often unknown to them. Even after hiring them, they are not provided with needed training for this perilous job (Hossain, et al., 2016). The essential Personal Protective Equipment (PPE) is not provided to the workers (Das and Shahin, 2019). Workers here dismantle ships with their bare hands and often are compelled to work overtime more than their ability (Hossain and Islam, 2006). Exposure to heavy metals poses a great risk to the health of the laborers. They inhale noxious substances like asbestos without knowing the consequences. Besides the laborers are also exposed to toxic paints, such as Tribtylin (TBT) which is another threat for them. The cutting process takes place under powerful cutting torches and the exposure to the emitted light causes problems like burring sensation, blurry vision, tearing, and eye redness (Zakaria, et al., 2012). Working long hours in an unbearable noisy environment, some workers often suffer from hearing impairment. Pure drinking water, nutritious food, safe sanitation, and livable housing are largely absent in these shipbreaking yards. Lack of hygiene facilities often forces the workers to return to their living place without taking a bath, which escalates the risk of disease transmission among them. Even if someone leaves the dirty job, health issues won’t leave him. Specific types of cancer can occur after 15 to 20 years to those who are exposed to toxic fumes and materials for a long time.

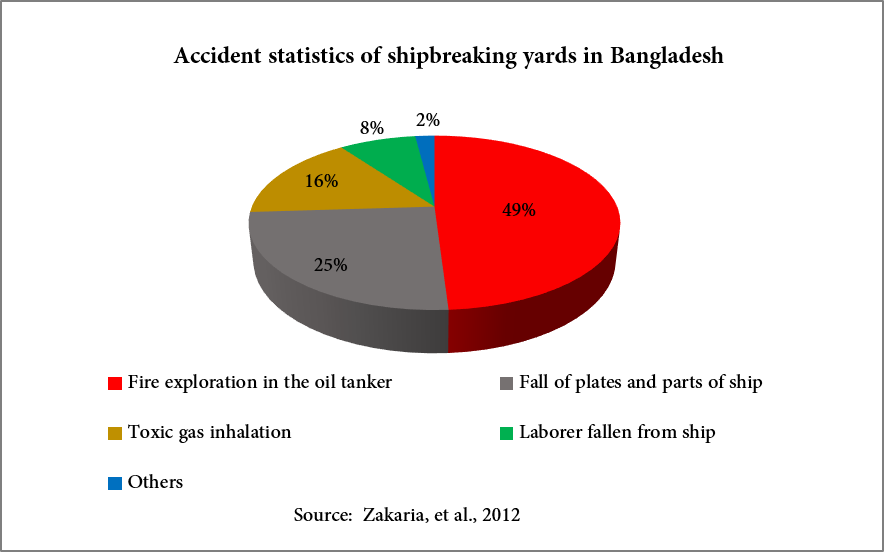

Hazards and accidents are regular phenomena in these shipbreaking yards. Explosions and accidents do not get reported even if they occur frequently. Bangladeshi government does not have an authentic record of the accidents that took place in the inhuman conditioned shipbreaking yards (Shameem, 2012). Research shows that approximately 50% of the accidents are caused by fire exploration.

Small scale hazard incidents are often considered as “isolated events” and authorities do not bother themselves investigating these “trivial issues”. Only when the blast is apparent to the outsiders, it gets media coverage.

Death of 10-15 labors and injuries to another 150 is the average annual scenario of the shipbreaking yards of Bangladesh (Das and Shahin, 2019). Young Power in Social Action (YPSA) says, the year 2013 saw 22 incidents of death and the following year left 7 labors dead and over one hundred injured (Jobaid, et al., 2014). Approximately 1000-2000 deaths occurred in the last 30 years and the number of laborers suffering from diseases remains uncounted (Hossain, et al., 2016). The shipbreaking industry has turned into a killer, which runs the economy with the heavy price of human lives. The pathetic voyage of workers does not end in their death, rather goes on through the suffering of their families, who do not get a minimum level of compensation to turn around.

Another growing concern in these yards is increasing child labor. 18 to 22 aged laborers are mostly found in the shipbreaking yards while under 13 aged comprise 10% of the workforce (Jobaid, et al., 2014). Children have become the frequent choice of recruiters since they can be easily exploited in terms of payment. Bangladesh Shishu Adhikar Forum (BASF) raised concern about the “dangerous work environment” of the shipbreaking yards for children. However, children from the poverty-torn northern region of Bangladesh are getting involved in this life-threatening job to support their families.

Unread diary of victims: the death of Mohidul and Mollah

Greenpeace and FIDH (International Federation for Human Rights) in cooperation with a local NGO YPSA (Young Power in Social Action) collected individual stories of the victims and testimonies of the family members back in 2005, to uncover the shocking reality which is often left unheard. Mohidul, aged only 25 joined a shipbreaking yard in Chittagong after his homestead got vanished from a tornado. Surviving the everyday challenge of staying safe in the precarious job, he was planning to get married and start a family of his own. In September of 2005, a massive piece of iron hit on his chest while manually dismantling an old ship. With immense bleeding and a broken leg, Mohidul was hospitalized. He required an operation to survive, but the cruel yard authority refused to offer financial help. He died in October being deprived of his rightful medical support. His family received only the cost of transporting the dead body and funeral procedures.

13 years after Mohidul’s departure, the deathtraps are still in place in these shipbreaking yards. Vidal (2020) revealed the cause behind the death of another unfortunate laborer Khalid, whose fate was indifferent to Mohidul. With no education and experience, Khalid was a “low pay fit” for the shipbreaking job. He was working without holidays, seven days a week, and over 12 hours a day. His laborious life came to an end in march of 2018 when he accidentally fell from the 8th story of a supertanker. 50,000 BDT was set for the compensation of the deceased, which was far from the need. Maran (UK) Ltd. owned the tanker straight before its passage to Chittagong and the company is not innocent of foreseeing the accident, according to a London law firm Leigh Day. Bangladesh is taken advantage of by rich ship owners, to get the high price even after knowing that laborers’ lives will be insecure and defenseless. These two incidents are just a snippet of the many untold, unrecorded stories which depict the life of the workers as “replaceable items” for the shipbreaking yards.

Legal aspects in Bangladesh and implementation barriers

There are several international legal regulations on shipbreaking such as –Guidelines of the IMO (International Maritime Organization) and ILO (International Labor Organization), Basel Convention, Rotterdam Convention, etc. Shipbreaking nations have to abide by these regulations even if they are not necessarily translated to their national laws. In Bangladesh, Ship Building and Ship Recycling Board (SBSRB) was established under “Shipbreaking and recycling rules” of the Ministry of Development in 2011. The board issues certificates to the ships that can be dismantled without serious risk. However, the success of the board is questioned since the death toll of laborers gained international media attention in the following years. In 2018, the parliament passed the “Bangladesh Ship Recycling Bill” which imposes bigger punishment for violating environmental and labor rights laws. It orders the establishment of a separate zone only for shipbreaking yards. 2 years in prison and fines of 10-30 lac BDT will be punished for building yard without permission of the authority and importing ships that do not have a no-objection-certificate. Issuing life insurances for every worker has been made compulsory for the yard owners.

The bill seems to be effectively formulated considering the hazardous impacts of the shipbreaking yards. However, there are some hindrances towards proper implication of the bill, that have been developed for years of negligence. The institutional arrangement is a major challenge to ensure the rule of law. Numerous government bodies deal with shipbreaking but there is no defined boundary of their roles. Ministry of Industries, Department of Customs, Ministry of Labour and Employment, Inland Water Transport Authority, Bangladesh Navy, Chittagong Port Authority are some of the responsible government departments. Establishing a legal body that will handle all the responsibilities of shipbreaking and recycling can be a viable solution for effective management. This body can be made from experts of different sectors who will ensure environmental and labor justice in the field. Another great challenge is to record certain necessary information. The recording is needed to build up a reliable information source regarding the number of imported ships, their countries of origin, the number of laborers dead or injured in the workplace, etc. The recorded information can be annually published which can be scrutinized to find places of improvements. Bangladesh is currently lacking an international standard inspection system (Alam and Faruque, 2014). It has to be developed to ensure that hazardous waste is managed properly and labor rights are given utmost attention.

Safeguarding environment and its people: green ship recycling prospects

Green ship recycling is becoming an increasingly famous and feasible way to address the adverse impacts of shipbreaking yards. Unlike traditional recycling, it keeps a careful eye on the reduction and proper management of hazardous waste so that the maritime environment is free of risk. This responsible form of ship recycling is promoted by the International Maritime Organization’s Hong Kong International Convention in 2009. There will be green recycling centers equipped with dry-dock facilities for waste management and the disposal of waste will be directed at avoiding waterways (Mambra, 2020). Moreover, it will provide a protective workplace for thousands of workers- whose health and safety will be a priority to the authorities.

Other large shipbreaking nations like India, Pakistan, and Turkey have taken initiatives to turn their shipbreaking yards into green yards. PHP Ship Recycling Yard is the only Hong Kong Convention certified green yard in Bangladesh to date (Das and Shahin, 2019). Bangladesh government has set a deadline of February 2023 to turn all the existing yards into green yards, but the huge cost of the transformation process is creating reluctance among the yard owners. There is around a 50% drop in scrap pricing this year due to the pandemic (Illius, 2020). However, the Bangladesh government asked for foreign financial assistance to continue its green yard journey. Norway already offered support of 1.5 million USD to improve the ship recycling standard of Bangladesh. It is to see now how sincerely Bangladesh authority handles responsibilities to reach the target.

Conclusion

The shipbreaking yards in Bangladesh shows us a dual face of the rich northern hemisphere, which treats their very own surrounding as the only implementation arena of global agreements. From the research evidence, we also see how a nation like Bangladesh devalues its invaluable marine ecology and workers’ lives ignoring laws and regulations. However, the recent stepping up of the Bangladeshi government along with the support of its foreign counterparts is raising hope for a better future. For Bangladesh, it will take a while to wipe off the taints of lost lives and the damaged environment from the record book of the shipbreaking industry, but the journey must go on.

Writer: Sumaiya Siddique Department of Geography and Environment, University of Dhaka.

References

- Aktaruzzaman, M., Chowdhury M. A. Z., Fardous, Z., Alam, M. K., Hossain, M. S. & Fakhruddin, A. N. M. (2014). Ecological Risk Posed by Heavy Metals Contamination of Ship Breaking Yards in Bangladesh. International Journal of Environmental Research, 8(2), 469-478.

- Alam, S. & Faruque, A. (2014). Legal regulation of the shipbreaking industry in Bangladesh: The international regulatory framework and domestic implementation challenges. Marine Policy, 47, 46-56. http://dx.doi.org/10.1016/j.marpol.2014.01.022

- Das, J. & Shahin, M. A. (2019). Ship Breaking and its Future in Bangladesh. Journal of Ocean and Coastal Economics, 6(2). https://doi.org/10.15351/2373-8456.1110

- Demaria, F. (2010). Shipbreaking at Alang-Sosiya (India): An ecological distribution conflict. Ecological Economics, 70(2), 250-260. https://doi.org/10.1016/j.ecolecon.2010.09.006

- Gunbeyaz, S.A., Kurt, R.E. & Baumler, R. (2019). A study on evaluating the status of current occupational training in the ship recycling industry in Bangladesh. WMU Journal of Maritime Affairs 18, 41–59. https://doi.org/10.1007/s13437-019-00164-0

- Hossain, K.H. (2015). Overview of Ship Recycling Industry of Bangladesh. Journal of Environmental & Analytical Toxicology, 5(5). http://dx.doi.org/10.4172/2161-0525.1000312

- Hossain, M.M.M. & Islam, M.M. (2006). Ship Breaking Activities and its Impact on the Coastal Zone of Chittagong, Bangladesh: Towards Sustainable Management. Young Power in Social Action (YPSA).

- Hossain, M.M.M. & Rahman. M.A. (2010). Ship breaking activities: threats to coastal environment and fish biodiversity. In. M.E. Hoq, A.K.Y. Haroon and M.G. Hussain (Eds.), Eco-system Health and Management of Pollution in the Bay of Bengal. Support to Sustainable Management of the BOBLME Project, Bangladesh Fisheries Research Institute (BFRI).

- Hossain, M.S., Fakhruddin, A.N.M., Chowdhury, M.A.Z. & Gan, S.H. (2016). Impact of ship-Breaking activities on the coastal environment of Bangladesh and a management system for its sustainability. Environmental Science & Policy, 60, 84-94. https://doi.org/10.1016/j.envsci.2016.03.005

- Illius, S. (2020, August 17). Green ship-breaking yards still a far cry. The Business Standard. https://tbsnews.net/economy/industry/green-ship-breaking-yards-still-far-cry-120394

- Jobaid, M.I., Khna, M.M., Haque, A.K.M.K. & Shawon, I.A. (2014). Ship Recycling and Its Environmental Impact: A Brief Overview of Bangladesh. IOSR Journal of Business and Management (IOSR-JBM), 16(10), 31-37. doi: 10.9790/487X-161013137

- Khan, J.U. (2010, March 7). Steel exports shine. The Daily Star. https://www.thedailystar.net/news-detail-128986

- Kutub, M. J. R., Falgunee, N., Nawfee, S. M., & Rabby, Y. W. (2017). Ship breaking industries and their impacts on the local people and environment of coastal areas of Bangladesh. DE GRUYTER OPEN, HSS, VI (2), 35-58. doi: 10.1515/hssr -2017-0013

- Mambra, S. (2020, May 29). What is Green Ship Recycling? Marine Insight. https://www.marineinsight.com/environment/what-is-green-ship-recycling/#:~:text=As%20a%20way%20of%20responsible,its%20impact%20on%20the%20environment.

- Pasha, M., Mahmood, A.H., Rahman, I. & Hasnat, A. (2012, May 26-27). Assessment of ship Breaking and recycling industries in Bangladesh—an effective step towards the achievement of environmental sustainability. [Paper presentation]

International conference on agricultural, environment and biological sciences (ICAEBS’2012) Phuket, Thailand - Rabbi, H.R. & Rahman, A. (2017). Ship Breaking and Recycling Industry of Bangladesh; Issues and Challenges. Procedia Engineering, 194, 254 – 259. https://doi.org/10.1016/j.proeng.2017.08.143

- Rahman, S.M.M. (2020). A Critical Review of Shipbreaking Literature Reveals Shortcomings in Dimensions Considered for Sustainability. Preprints. http://dx.doi.org/10.20944/preprints202009.0121.v1

- Shameem, K.A.B.M. (2012). The role of the ship breaking industry in Bangladesh and its future with special emphasis on capacity building through education and training [MSc dissertation, World Maritime University]. World Maritime University Dissertations.

https://commons.wmu.se/all_dissertations/13 - Siddiquee, N.A., Parween S., Quddus M.M.A. & Barua P. (2012) Heavy Metal Pollution in Sediments at Ship Breaking Area of Bangladesh. In: Subramanian V. (eds) Coastal Environments: Focus on Asian Regions. Springer, Dordrecht. https://doi.org/10.1007/978-90-481-3002-3_6

- Sujauddin, M., Koide, R., Komatsu, T., Hossain, M.M., Tokoro, C. & Murakami, S. (2015). Characterization of ship breaking industry in Bangladesh. Journal of Material Cycles and Waste Management 17(1), 72–83. https://doi.org/10.1007/s10163-013-0224-8

- Sayem, A. (2020, July 18). Ship-breaking sector feels the chill. The Business Standard.

https://tbsnews.net/economy/industry/ship-breaking-sector-feels-chill-107899 - Vidal, J. (2020, January, 31). ‘Mollah’s life was typical’: the deadly ship graveyards of Bangladesh. The Guardian. https://www.theguardian.com/global-development/2020/jan/31/khalid-mollah-life-was-typical-the-deadly-ship-graveyards-of-bangladesh

- Zakaria, N.M.G., Ali, M.T. & Hossain, K.A. (2012). Underlying problems of ship recycling industries in Bangladesh and way forward. Journal of Naval Architecture and Marine Engineering, 9(2), 91-102. https://doi.org/10.3329/jname.v9i2.10515